Introduction

Work check at Wieland

Open exchange of experience between plant managers and lean managers

What can you expect from a plant check?

How does my plant compare to the benchmark? This question is a recurring concern for factory managers. A group of plant managers got together 15 years ago and defined a one-day format that combines a lively exchange of experiences with impulses from the best factories.

- The focus is on the host plant - Wieland in Ulm on November 14.

- The participants are practitioners from other companies - those responsible for plant, production and value creation systems (Lean, TPM, Kaizen, CIP, ...).

- In an intensive 2.5-hour factory tour with prepared stations on key topics, all participants gain a comprehensive insight into the processes.

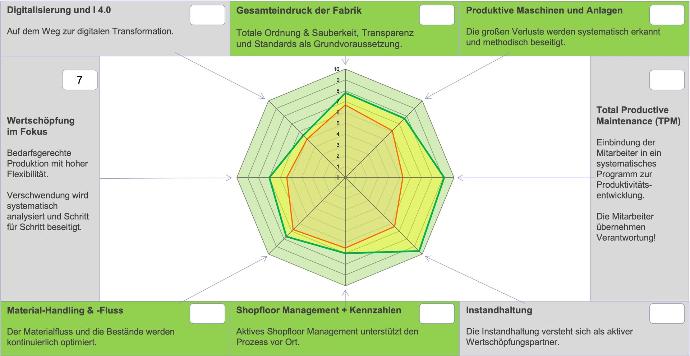

- In a moderated assessment, experiences, current trends and best practices are exchanged on 15 selected key topics and the status of the factory visited is jointly evaluated.

- Finally, target states and sensible steps are defined for selected fields of action.

- The host company receives valuable input from practitioners.The external participants experience good examples live on site and exchange experiences at eye level.

Key topics at Wieland

The following main topics have been prepared for the plant check at Wieland on November 14, 2024:

Factory - overall impression and transparency

- Total order & cleanliness as a basic requirement

- Working with standards & markings

Productive machines and systems

- Plant condition + employee involvement

- OEE / GEFF system

- Detection and elimination of center of gravity losses

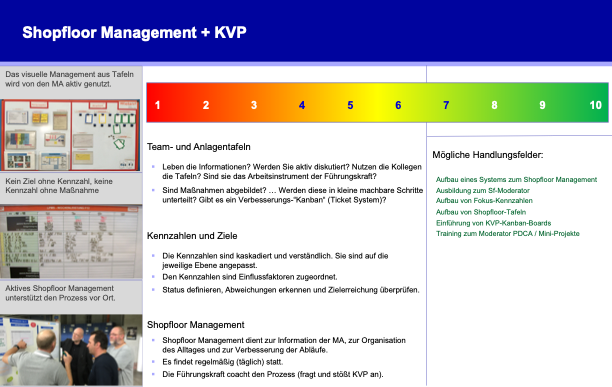

Shopfloor management + CIP

- Team & system boards

- Working with key figures / KPIs

- Moderation of store floor meetings

Material handling & flow

- Directed material flow without waste

- One-stock strategy and minimum stocks

- Efficient load carriers

Further information about Wieland and the “Engineered Products” division can be found here ...