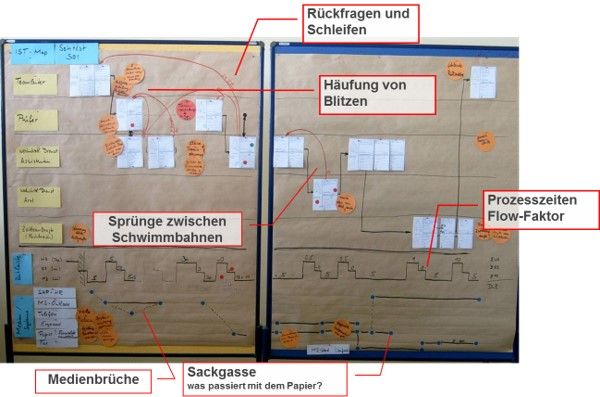

Value stream mapping

TRANSPARENTLY DISPLAYING VALUE FLOWS AND OPTIMIZING THEM ACCORDING TO LEAN PRINCIPLES

TRANSPARENTLY DISPLAYING VALUE FLOWS AND OPTIMIZING THEM ACCORDING TO LEAN PRINCIPLES

Goal of the workshop:

Optimization of material flow and information flow within production with regard to throughput times, inventories, areas and the synchronization of work processes.

Procedure:

-

Transparent representation of the current situation (Cuurent state map).

-

Description of the process (value stream) from the perspective of a representative component or starting material across all value creation steps.

-

Determination and calculation of current key figures for the process (throughput time vs. processing time, distances as meters traveled in the factory, handling steps on the component (manual handling, forklift movements, stock levels, number of storage locations, container sizes and lot sizes)

The process:

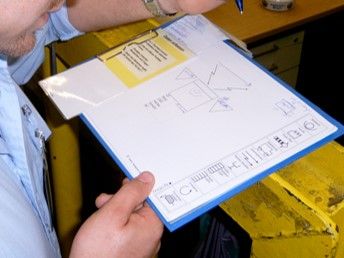

1.short theoretical introduction to the method and the tools

2. exercise on the application of the value stream symbols and calculation steps.

3. application of the method to a practical example in the factory:

-

Recording the actual situation through observations (each participant is assigned a specific role)

-

Creation of the Current-State-Map (actual situation)

-

Impulses for optimization from lean principles

-

Building a target state and a future-state map

-

Derivation of measures and projects to achieve the target state

*You will learn to apply all lean principles to the value stream of a specific part.

Workshop / training fee: from 1.900,- Euro plus statutory value added tax

Workshop / training fee: from 1.900,- Euro plus statutory value added tax