Overview

Lean Master Training at Daimler Truck

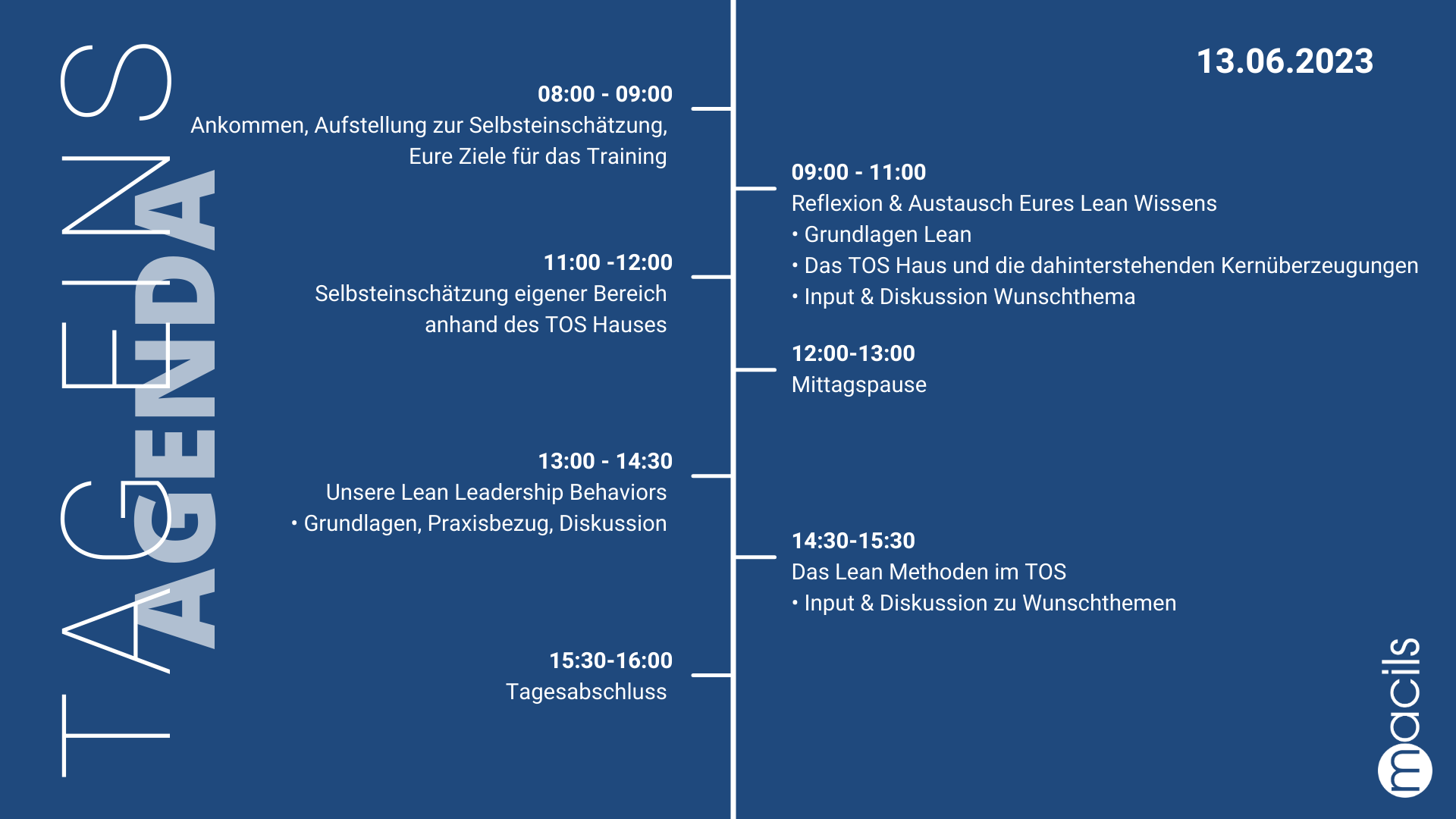

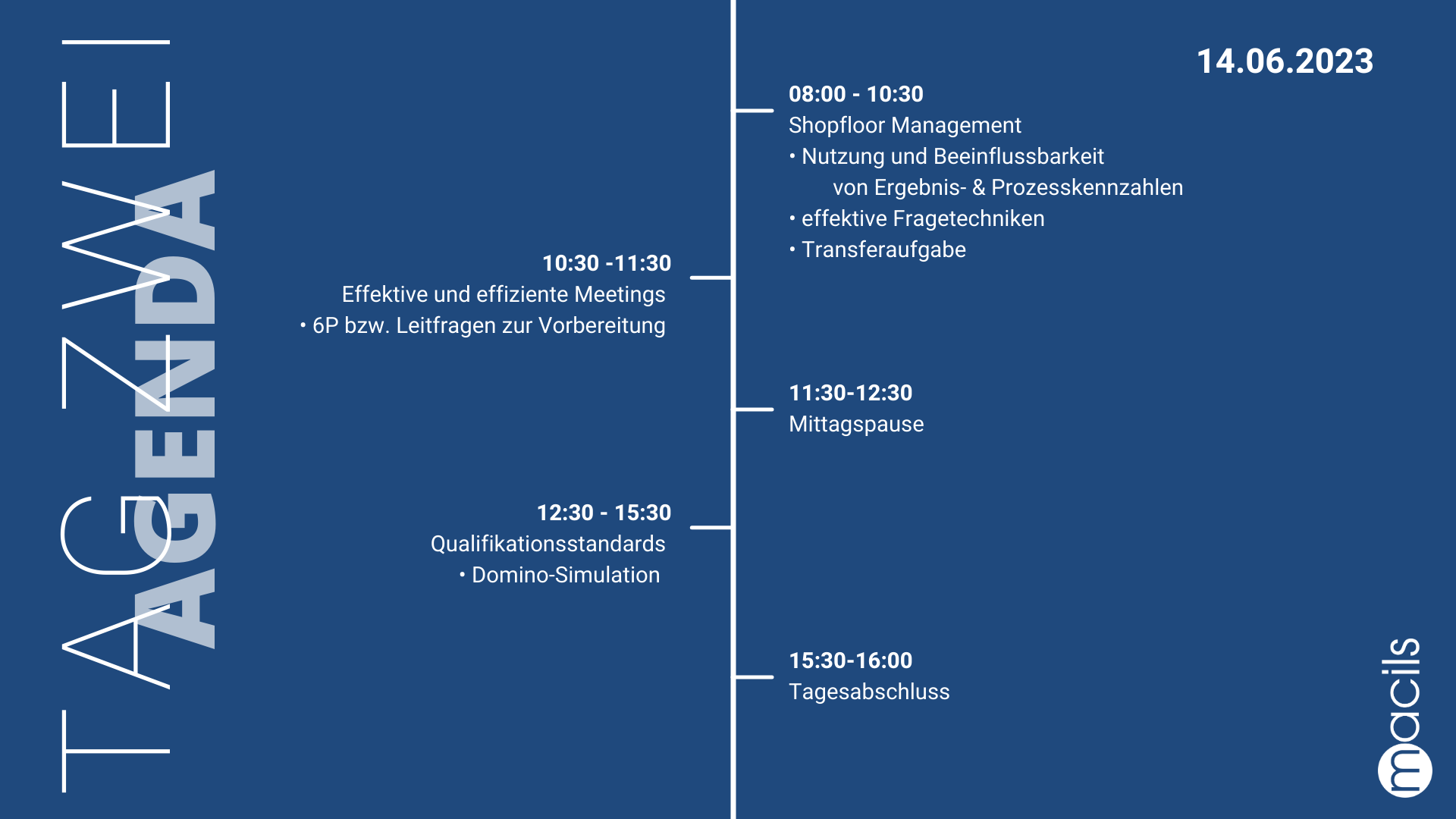

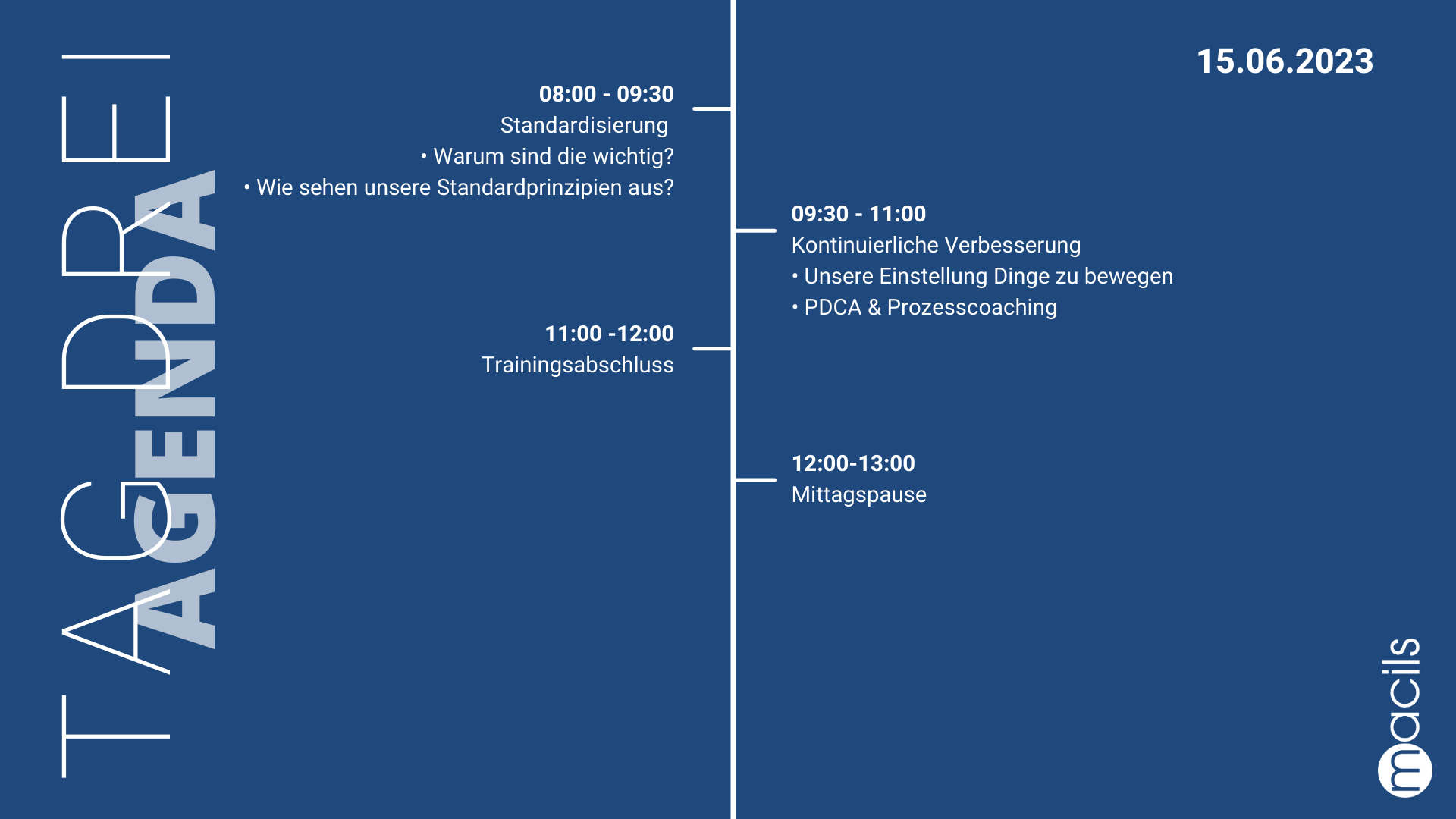

3-day Lean Methods and Leadership Training

Führung vor Ort – Der Meister sichert die Produktivität der Fabrik

The performance of the entire factory is decided on the shop floor. This is where a lean culture is exemplified and passed on to the employees. This is where problems and waste are identified and where productivity potentials are raised through a lively kaizen and improvement process. But how do you prepare foremen for their important leadership role?

Daimler Truck trains the first manager on the shop floor (foreman, group leader, shift foreman, ...) in a special lean training and shares the experience with interested companies for the first time. The participants experience the individual training modules live on site at Daimler Truck in Wörth during a 3-day training.

Target

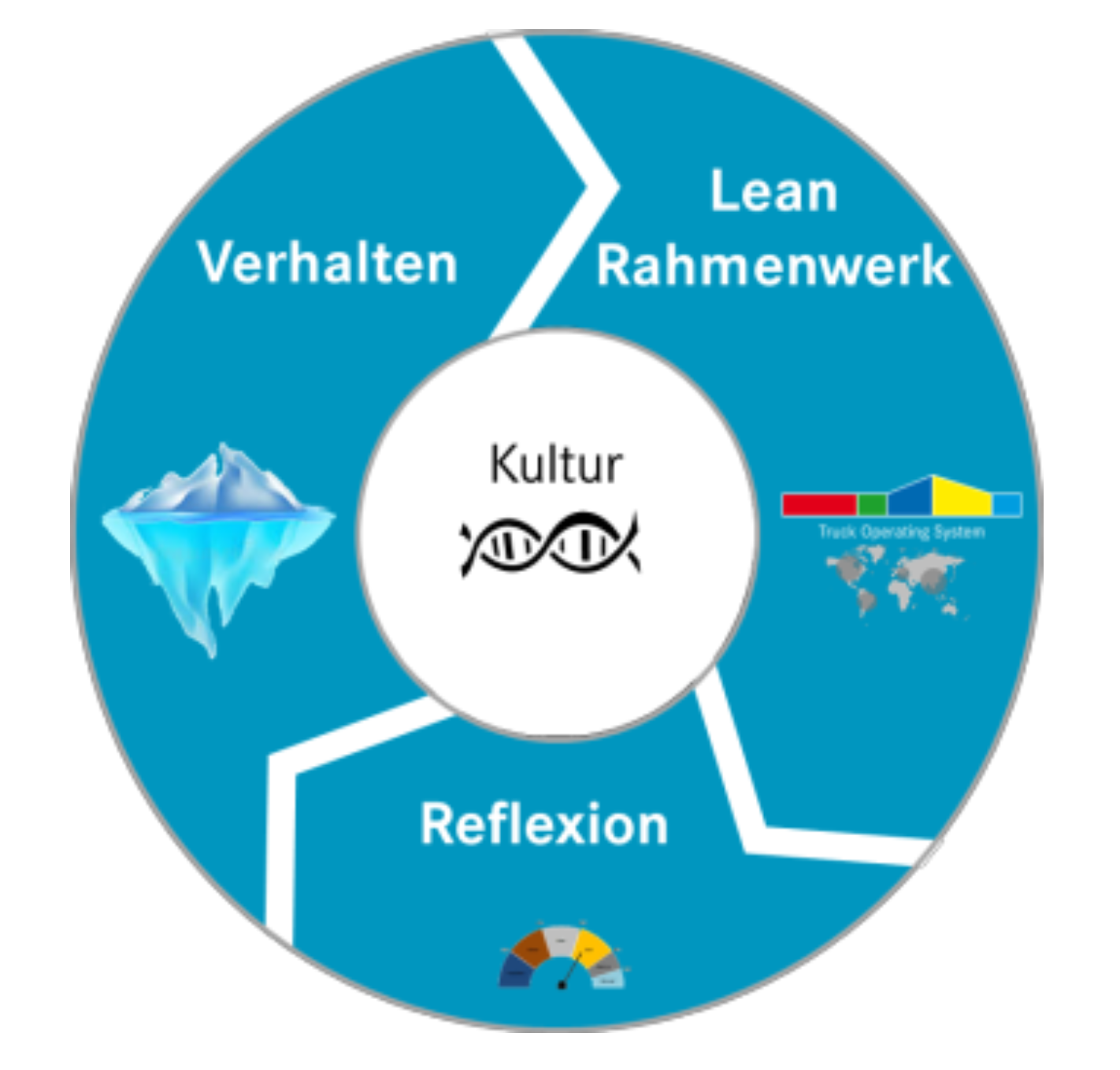

Strengthening the lean culture at foreman level and insights into the building blocks of Daimler's Truck Operating System (TOS).

What is it about?

The training aims above all to strengthen the lean culture and to reflect on the application of a production system (using TOS as an example) as prospective managers in order to be able to implement it practically in everyday work. To do this, we not only look at helpful TOS methods, but also at behaviour (Lean Leadership Behaviors). The training includes many entertaining exercises to reflect on both. Self-reflection Lean & TOS topics.

Main focus

- Employees & Leadership

- Shopfloor Management

- Standardisation

- KVP(Continuous Improvement Process)

-

PDCA & Prozesscoaching