Overview

Live-Training

Lean- and TPM practitioner

Seven-day certificate training for lean multipliers and TPM experts,

who take on a new role in practical lean implementation

All modules take place live in factories with practical relevance

Start of training at Wieland-Werke AG in Villingen (TPM Factory of the Year)

Basis are the Lean principles and tools

Fit for the role of lean multiplier in your factory?

Seven-day, paxis-oriented training in three blocks:

Participation fee: 2,950 euros plus statutory value-added tax

Special features of this live training :

- The training was developed in a practical way in a group of successful TPM and Lean companies and has been successfully carried out for over 10 years

- Start of training at Wieland, one of the best TPM factories

- All modules take place live in companies, ensuring a direct link to practice.

- Lean methods are combined with social skills training

- Access to many best practices

- Option to implement your own project in parallel and present it in a digital degree

target group:

- Selected new multipliers, trainers and facilitators

- Experienced practitioners who take on a new role in CIP

- future supporters of the improvement process

- prospective CIP coordinators and process facilitators, new project managers, kaizen managers

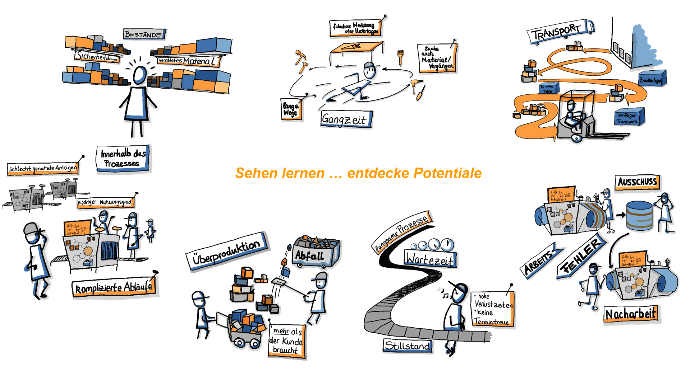

What you will learn in this 7-day training:

- the basic Lean methods and tools

- understanding your role and success factors as a multiplier

- Successfully plan, manage and secure improvements and workshops

- lively moderation and interaction techniques in the team

-

Confident handling of conflicts

- The foundations for ensuring sustainable results

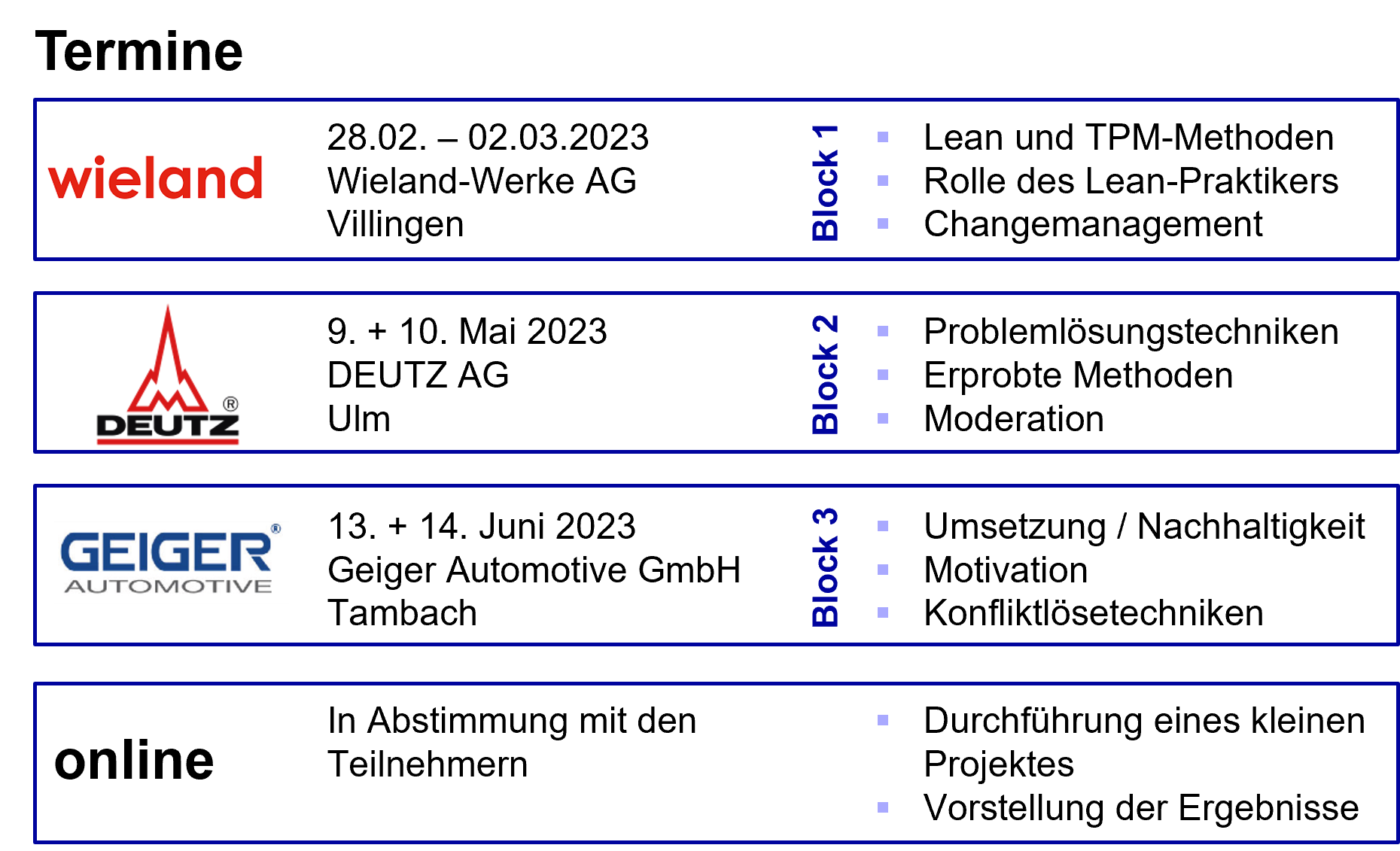

Block 1 at Wieland-Werke AG:

Day 1 - 28.02.2023

TPM at Wieland: Insights into practice with many live stations

- TPM level on equipment

- OEE acquisition and optimization

- Die Rolle der Instandhaltung als PartnerOEE acquisition and optimization

- Optimization standards

- Shopfloor Management

- Involving employees in the change process

- Establishment of a TPM / Lean system

- Understanding the Lean principles

- The role of the lean practitioner

Day 2 - 01.03.2023

Method overview of Lean and TPM

- TPM Pillar Model

- Autonomous maintenance

- Planned maintenance

- Detection and elimination of center of gravity losses

- 5S as a basis

Day 3- 02.03.2023

The role of the lean practitioner in the change process

- Recognize, learn and solve blockades and resistances

- Professionally accompany changes as a change manager

- Successfully implement CIP methods in the company

- Basics of agile project management and simple SCRUM tools

Block 2 at Deutz AG:

Day 4 - 09.05.2023

Facilitation and communication as a Lean and TPM practitioner.

- Basic principles of moderation

- Structure and preparation of a moderation and the role of the moderator

- Moderation techniques and rhetoric. Suggestions for small group moderation, rhetorical tips and tricks.

- Procedure of a group meeting or workshop

Day 5 - 10.05.2023

Solve problems systematically

- Problem-solving cycles from problem identification to implementation

- Procedure and visualization for problem description

- Procedure and visualization for root cause analysis

- Procedure and visualization in finding solutions

- Exercises based on practical examples in the factory

Block 3 at Geiger Automotive GmbH:

Day 6 - 13.06.2023

Lean and TPM tools for process optimization

- Power set-up as a success factor

- Analyze value streams and optimize throughput times

- Visualize processes

- Lean in the Office - Where are the Differences?

- Exercises in the factory

Day 7 - 14.06.2023

Motivation and coaching in the team and sustainability in implementation

- Perception, analysis, handling and management of conflicts

- How to motivate participants in the workshop

- Coaching in dealing with conflicts

- Sustainability in the CIP process

- Guard rails of a successful audit

Each block includes method training and social skills training. In some cases, these are combined in exercises. The detailed planning of the individual day's content is geared to the possibilities of practical exercises in the host factories. A detailed agenda will be agreed with the participants at the beginning of each block..

Conduct your own hands-on project (optional):

All participants have the opportunity to carry out a practical project in their own company parallel to the training. If desired, you will be coached and have the opportunity to present the results to the team in an online presentation.