Introduction

Transfer workshop:

Material flow and inventory optimization

Two-day live training at the Wieland AG plant in Villingen, Germany

on 21 + 22 November 2023

When optimizing processes in a factory, there is no getting around inventory issues, material flows, throughput times and all the associated optimization tools. At Wieland as a manufacturer of semi-finished products, these topics are of high importance and are driven forward by trained coodinators within the framework of Lean, CIP (Continous Improvement Process) and TPM. The Villingen plant is often a pioneer in the Wieland Group and was named TPM Factory of the Year a few years ago.

In this two-day transfer workshop on November 21 + 22, 2023, participants will have the opportunity to get to know the factory and learn about the methods and tools for optimizing material flows and inventories in a mixture of technical impulses and lively simulation exercises. All topics will be reproduced live in the factory.

This transfer workshop is included in the membership fee for all member companies that have booked the transfer workshop option. The other participants of the learning journey can book it for a special price of EUR 600,-. The invoice can be issued either directly or together with the membership fee at the end of the project half-years.

Objective

Getting to know control types for material flow and inventory optimization within production with a view to throughput times, inventories, areas and clocking out of operations and their application in practice.

Participants experience the possibilities and influences of the methods directly in the plant and then learn to apply them to their own processes.

Content

- Impulses from the lean methods / toolbox

- Necessities and effect of inventory optimization

- Push and pull principles

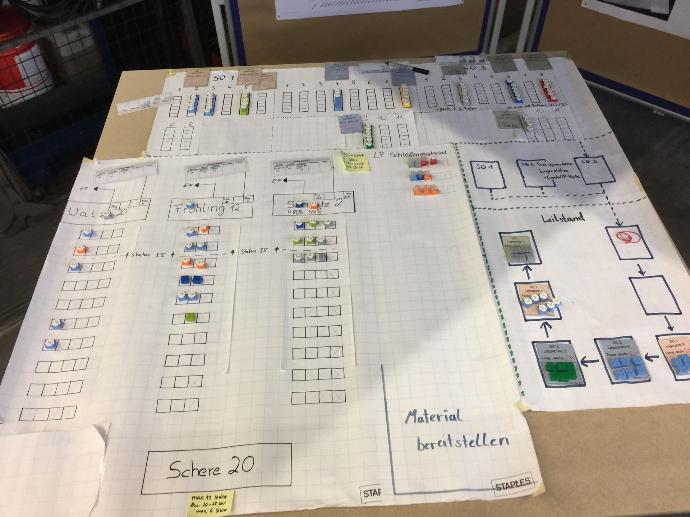

- Learning projects and simulations

Experiencing the methods in the live processes at Wieland

- Kanban

- FiFo

- ConWIP

- Workload Control

- Transport routines

Procedure

The training takes place live on site at the Wieland plant in Villingen and is conducted by experienced lean trainers from the Wieland Group.

The mixture of method input, learning exercises and experiencing the implementation in the plant is complemented by the exchange of experiences of the participants from different companies and industries.